The first case

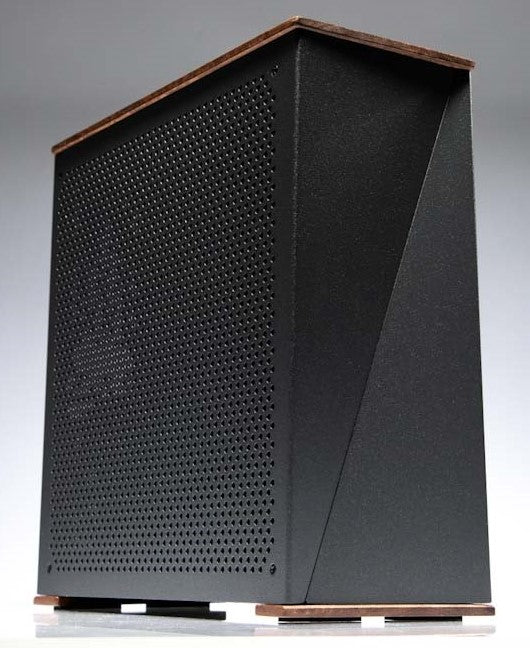

This is my first case project. I wanted a small case that can still house respectable hardware, and this is the layout I came up with. The SFX psu is hidden behind the GPU and under the motherboard.

Making this was exciting, and challenging. I was still unfamiliar with bending sheet metal so everything is made from flat panels cut on a CNC from 1mm aluminum, welded together and powder coated. The backing is poplar wood, also CNCed and glued to the metal.

My primary takeaways were that welding is extremely expnsive, CNCing is very slow (in my home workshop), and I need to learn how to bend sheet metal

-

-

-

-

Here you can see the welds before powder coating

-

And this is the welding jig, holding everything in place

-

CNC-ed parts!

Carrying forward lessons learned

I quickly began work on the next iteration of this idea. Version two was going to be one (ish) piece of aluminum, laser cut professionally and CNC bent. Gone will be the wood back (because wood that wide is very hard to come by) and instead wood panels would adorn the top and bottom of the case.

Besides the structural changes, its also going to be a bit wider to house some fans at the back for just a little better cooling, and the plexi side panel can just slide into a groove in the wood. Better yet, I was sampling different colors. Pairing white frames with ash wood, grey with walnut, and black with wenge.

Nothing is ever quite perfect and there were new issues that arose from the redesign. There were two major concerns with these cases. Firstly, the plexi side panel sliding in was not the best idea; turns out if you don't screw it on it rattles with the vibration of the fans of the running computer and just sounds terrible. Secondly, and far more importantly, wood warps a lot! The wood tops and bottoms are pretty thin, and wood warping with heat and humidity cycles is incredibly powerful. It warps the aluminum frame. Either I had to use thicker wood to make it less prone to warping, or the wood couldnt be structural.

Putting it all together

Third time's the charm. This final iteration was taking all the lessons learned and putting them together into my first product. The construction became steel, the wood became purely decorative, and the case was expanded to take 280mm AIOs.

This was contracted out to be sold by Artesian Builds, and branded the Pluto. 100 production units were ordered, and as far as I am aware about 50 were sold before Artesian shut down. The remaining stock was acquired by Computer Headquarters and a few units of this case are still available for sale over on their website.

Overall I am extremely proud of how this has turned out. I had the privilege to speak with a couple customers who bought one over on Reddit and gather some feedback. I am however putting this case to rest, and archiving the design files as I begin working on something entirely new.

Some other mods

After the above transpired, I took a break from trying to make a product and isntead did a few projects for myself as fun little one offs. One of these was making a sliger SV540 front distro plate for a liquid cooled build.

This is my personal computer that I use for gaming and design work, so I just did what I felt looked good. The front distro plate is milled from cast acrylic and polished by hand, with the Pump hidden underneath in the IO cable routing area. It gives the entire build the illusion of being fully submerged in coolant.

The metal pieces wrapping the distro (as it adds some thickness), were custom made to wrap around and mate with the OEM panels. Sliger was kind enough to take them and powder coat in the OEM colours in his production facility for a perfect match.